Understanding the Different Types of Circuit Card Assembly Techniques

Have you ever wondered what goes into making the gadgets you use every day work so smoothly?

The answer lies in a process called circuit card assembly (CCA). This article will take you through the different types of CCA techniques, making it easier for you to understand how your favorite electronic devices come to life.

Whether you’re a technology enthusiast or just curious, you’ll find the information easy to grasp, engaging, and directly relevant to the world around you.

Through-Hole Technology (THT)

Through-Hole Technology (THT) is a way to put together circuit cards where parts are connected to each other with pins. After holes are made in the circuit board, these pins are put in and soldered to pads on the other side.

This method makes sure that the mechanical and electrical connections between the circuit board and the parts are strong. It works really well for bigger parts or parts that need to be able to handle mechanical stress.

Surface Mount Technology (SMT)

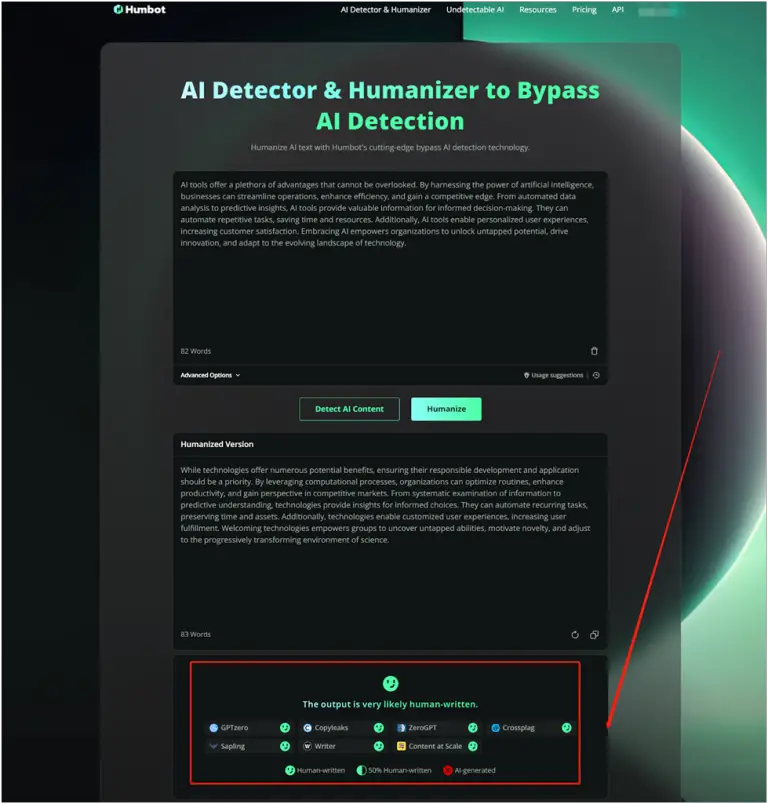

Surface Mount Technology (SMT) is another crucial technique used in the world of circuit card assembly. Unlike Through-Hole Technology, SMT involves placing components of a circuit board directly onto its surface.

The adoption of SMT has revolutionized the electronics manufacturing industry, allowing for the production of more compact, yet highly powerful devices. This makes SMT a preferred choice for panel building and assembly services aiming to meet the evolving needs of technology enthusiasts and professionals alike.

Mixed Technology

Made with Mixed Technology, circuit cards are made with both Through-Hole Technology (THT) and Surface Mount Technology (SMT). With this method, the best parts of both processes can be used in a single product.

Some makers can put a lot of different parts on one circuit board by using Mixed Technology. This method works great for electronic gadgets that need both the strong links of THT components and the small size of SMT components.

Chip-on-Board (COB)

With Chip-on-Board (COB) technology, the microchip is attached directly to the circuit board. A conductive glue is used to stick the chip to the board, and then wires are bonded directly between the chip and the board to make the links.

It takes up less room on the circuit board with this method because it doesn’t need separate chip carriers. COB is used a lot in things that need to save room and work efficiently, like LED lights and small electronics.

Ball Grid Array (BGA)

Ball Grid Array, or BGA, is a way to package integrated circuits on a flat surface. There are more pins that can be used for connections on a BGA package than on a dual in-line or flat package.

There are solder balls on the bottom of the package during the BGA process. The solder balls are then heated to connect the package to the circuit board’s copper pads. This makes a strong and reliable electrical link.

Mastering the Art of Circuit Card Assembly

In wrapping up our exploration of circuit card assembly, it’s clear how diverse and innovative the technologies behind our everyday gadgets are. Each technique, from THT to BGA, plays a unique role in bringing those devices to life.

By understanding these methods, we appreciate not just the gadgets themselves but the intricate processes they go through. PCB board assembly is truly an art and science, making our modern electronic world possible.

Was this article helpful to you? If so, make sure to check out our blog for more useful information and resources.