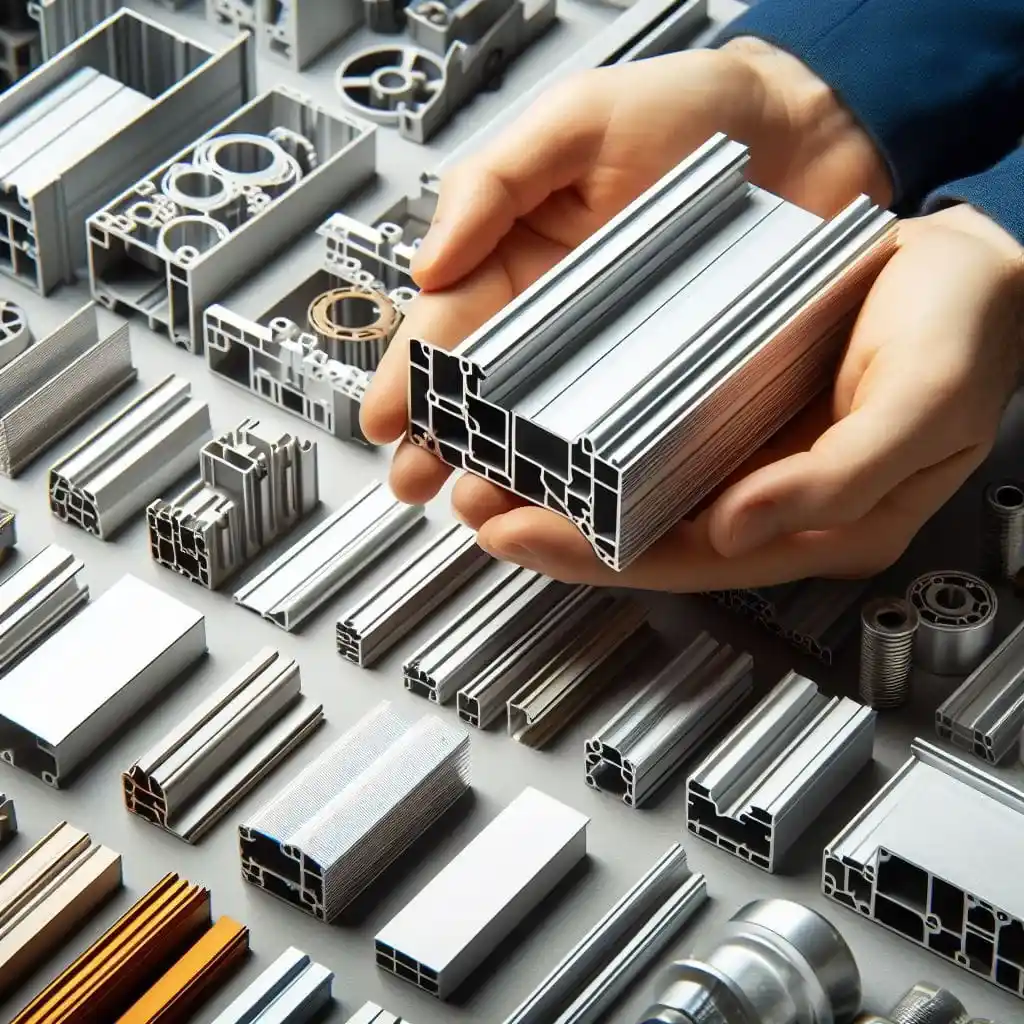

Choosing the Right Aluminum Channel Extrusions for Your Project

Have you ever found yourself standing in a hardware store, overwhelmed by the choices in front of you, especially when it comes to picking the right aluminum channel extrusions for your project? You’re not alone.

It makes a huge difference which aluminum channel you choose, whether you’re a do-it-yourself fan or a skilled maker. If you want to pick the right aluminum channel extrusions for your project, this article will help you understand the process and make it quick and easy.

Factors to Consider When Selecting Aluminum Channel Extrusions

Selecting aluminum channel extrusions involves considering various factors to ensure they meet your specific project requirements. Here are some key factors to consider:

Dimensions and Size

The measurements and sizes of the aluminum channel extrusions you choose are very important to the success of your project. You need to measure the area where you want to put the aluminum channel. This makes it more likely that the extrusion will fit properly and do its job well.

For instance, when looking at aluminum channels for structural projects, aluminium profile 40×40 is a popular choice due to its balance between size and strength. This profile is versatile and capable of supporting various profile design requirements and loads.

Alloy and Grade

Because they determine the material’s strength and rust protection, the alloy and grade of aluminum channel extrusions are important. Because they will be used in different places, different projects may need different alloy types. For jobs that will be done outside, pick an alloy that won’t rust. Each aluminum alloy has its unique properties that make it good for certain uses. If you want the aluminum channel to last a long time and keep its good looks, you need to choose the right alloy and grade. You can choose the best alloy and grade for your project if you know about the surroundings and what it needs.

Surface Finish

It’s important to think about the surface finish of aluminum channel extrusions because it affects both how the material looks and how long it lasts. Aluminum can last longer if it has a finish that keeps it from getting worn down. If the job is going to be outside, the surface finish may also change how well the metal resists rust. Where and how the aluminum channel will be used will help you choose the right surface finish. For projects that will be done inside, a simple mill finish might be enough. But for projects that will be used outside or in direct sunlight, you might need a more lasting finish like anodized or powder-coated. It’s important to choose the right surface finish for your job because each one has a different look and amount of safety.

Strength and Weight

An aluminum channel’s strength is very important because it tells you how much weight and pressure it can take without breaking or bending. This is very important for things that need to hold a lot of weight, like window and door frames or shelf units. To choose an aluminum channel with the right strength, think about how much weight your project will hold at its peak. Another important factor is weight. Heavier aluminum tubes offer more support and steadiness, but they can be harder to install. Depending on the type of job, lighter channels may be easier to work with while still giving you the strength you need. To make your project work well, you need to find the right mix between the aluminum channel’s weight and strength.

Corrosion Resistance

When selecting aluminum channel extrusions for your project, corrosion resistance is an important factor. This feature makes sure that the aluminum tubes can work in a variety of settings without breaking down. Choosing a material that doesn’t rust will make your project last longer and require less upkeep. An oxide layer grows naturally on the surface of aluminum, which makes it naturally resistant to rust. However, rust can be more likely in some places and under certain situations. So, it’s important to pick the right alloy and finish that will protect against rust even more, especially for projects that will be exposed to chemicals or tough weather.

Tolerances and Accuracy

For projects that need exact measures, tolerances and precision in aluminum channel extrusions are very important. Because of these things, the aluminum channels will fit well with other parts and won’t need any extra changes. A smooth and professional finish can be achieved for your project with the help of high accuracy in aluminum channel measurements. When choosing aluminum channel extrusions, it’s important to look at the limits listed in the manufacturer’s specs. These specs tell you how much the sizes of the aluminum channels can vary from one another. For projects where accuracy is important for the building and general function, it is necessary to choose extrusions with tight tolerances.

Supplier Selection and Reliability

When picking aluminum channel extrusions for your project, it’s important to think about how well-known and trustworthy the seller is. A trustworthy provider will make sure you get high-quality goods that meet your needs. Also, they have great customer service that can help you choose the right goods and answer any questions or address any worries you may have during your job. Being reliable means that the seller sends the right products on time and in good shape, so your project schedule doesn’t get pushed back too much. Suppliers who have a history of being reliable and making customers happy are more likely to offer steady quality and service. You can feel good about the things you use in your project if you buy them from a seller with a good name and a history of being reliable.

Environmental Considerations

The climate is becoming more and more important when picking goods for any job, such as aluminum channel extrusions. Earth will be better off if you use recycled aluminum or metal that can be retrieved for your project. It’s important to check out what the maker does to be eco-friendly and make sure it fits with your project’s environmental goals. For building and design projects, aluminum is very good for the world because it can be reused without losing any of its properties. When you choose aluminum channels that help with a cycle economy, you are being better for the earth. Check to see how energy-efficient the process is and if the item can be recovered. This will help the land handle your job better.

Tips for Cost-Effective Selection and Use of Aluminum Channels

When aiming for cost-effective selection and use of aluminum channels, keep the following tips in mind:

Bulk Purchasing

When you buy aluminum channel extrusions in bulk, you can save a lot of money. When a customer buys a lot at once, suppliers often offer lower prices per unit. This can be very helpful for big jobs or if you know you’ll need aluminum tubes for other projects in the future. But it’s important to have a clear plan for where to store the extra stuff. When you store aluminum channel extrusions the right way, you keep them safe from damage and rust so they stay in good shape until you need them. Making plans for how to store your big buy will help it stay in good shape over time.

Value Engineering

Value engineering is a technique for improving a project without giving up on its core goals. This method looks at every part of the aluminum channels to find ways to make them cheaper while still meeting the project’s goals and performance standards. People are more likely to make smart choices that help them get more out of their money and resources. It’s important to think about how helpful and long-lasting the project will be when using value engineering to pick aluminum channel extrusions. This means giving careful thought to the exact features of the aluminum channels that are needed and getting rid of any that aren’t necessary for the project to work.

Lifecycle Cost Analysis

Lifecycle cost analysis is a way to figure out how much it will cost to own an aluminum channel extrusion for its whole life. This includes the price you paid for it the first time, any costs for repairs or upkeep, and the cost of replacing it if necessary. By looking at the long-term financial effects as well as the short-term costs, it helps people make smart choices. This research is very important for projects that need to last and work well for a long time. It lets designers and project managers choose the aluminum channel extrusions that will give them the most value over time.

Elevate Your Project With Precision-Crafted Aluminum Channel Extrusions

It’s important that you pick the right aluminum channel extrusions for your job. If you pay attention to these things, your project will not only meet its form and function goals, but it will also last for a long time.

Remember, the decisions you make now about aluminum channels can greatly influence the overall quality and durability of your construction or design project. Make sure to pick wisely to achieve the best results.

Did you find the information in this article helpful? If so, be sure to check out our blog for more valuable resources.